The project spans 111km from Katra to Banihal, with 87% of the track built through tunnels, an extraordinary engineering feat that includes the construction of the Chenab Bridge, now officially the world’s highest railway bridge.

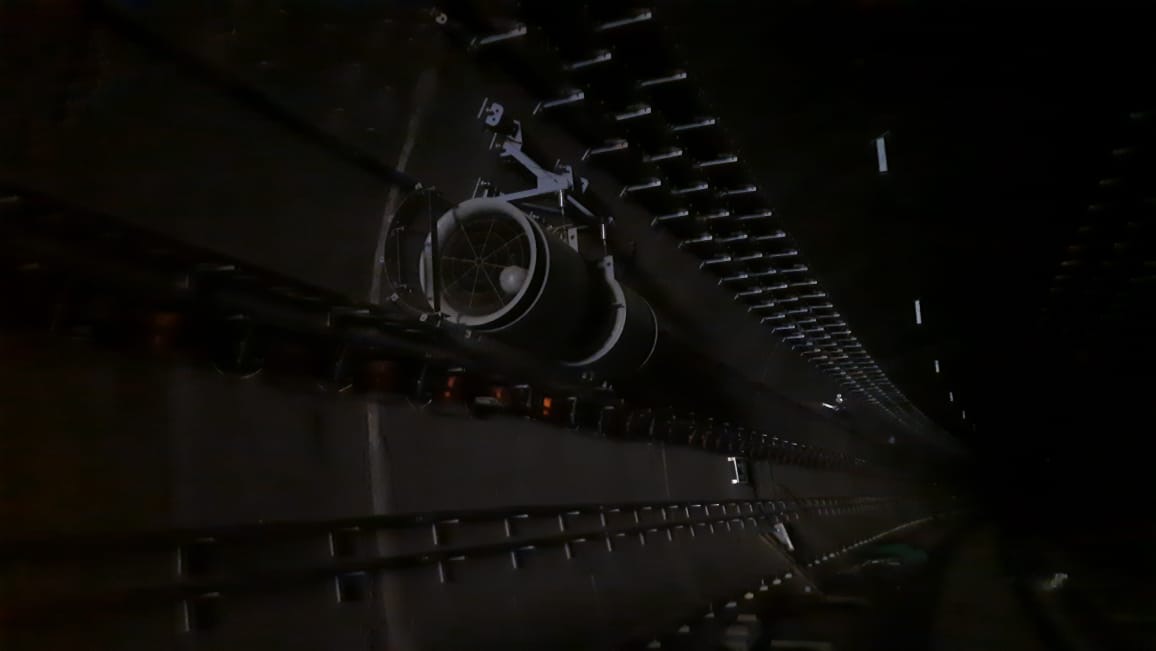

Among the many tunnels that required advanced ventilation, Tunnel No. 5 and Tunnel No. 6, located on either side of the Chenab Bridge, were of particular strategic and safety importance. We supplied reversible jet fans specifically for these tunnels, ensuring continuous airflow and enabling emergency smoke extraction in this high-altitude environment.

Our team supplied a complete range of high-performance ventilation products across several tunnels in the USBRL project, including:

All fans were delivered with a full accessory package and rated to withstand 400°C for 2 hours, providing reliable performance under both normal and emergency conditions, including smoke extraction and pollution control.

A unique highlight of this project was the solution delivered for Tunnel T14–T15, where spatial constraints posed a serious design challenge. We developed a bespoke low-profile silencer design that fit within the tight envelope while still achieving the necessary thrust output. This custom-engineered solution was key in delivering safe, compliant, and space-efficient tunnel ventilation without compromising on performance.

The successful delivery of this project reflects our global capability, engineering innovation, and the strong collaboration by working closely with the client throughout design, delivery, and implementation.

The USBRL project is more than a railway, it’s a symbol of national connectivity and infrastructure excellence. We are proud to have contributed technology that helps make this vision safe, sustainable, and operational.