Parking Garages - Pollution Control and Smoke Control - Part 3

Car Park mechanical ventilation systems can be broadly defined into three types: Pollution Only; Smoke Clearance or Purging; and Smoke Control. In this article we look at the characteristics of each type of installation, and how in each case a Jet Thrust System provides a more effective solution than a traditional Ducted System.

Pollution Only Systems

Pollution systems tend to be included in all mechanical ventilation systems for parking garages, as the day-to-day function. Pollution Only Systems, with no provision for emergency ventilation, are more typically installed on parking garages with a sufficient number of natural smoke outlets.

The requirements for these types of system, as defined in the regulations, can be as simple as a flow rate (per square meter of floor space), or they can be founded on an air change rate which is based on the volume of the occupied parking garages.

The third basis is a ventilation rate which is based on tabulated data taken from the pollution generated by a typical car when running or starting up, with the engine hot or cold. This type of design can be used to reduce the required ventilation rate (and hence running cost) of the system based on the expected usage, but it may require more design work because of its complex nature.

Ideally a Jet Thrust Pollution Only System would be designed for the maximum ventilation rate, but would also include active controls (including pollution detection) so that it can be ‘turned down’ during periods of limited activity. This may even result in periods when the system is in stand-by mode, which as well as saving energy and running costs, negates the need for ‘proof of pollution’ calculations associated with more complex ventilation standards.

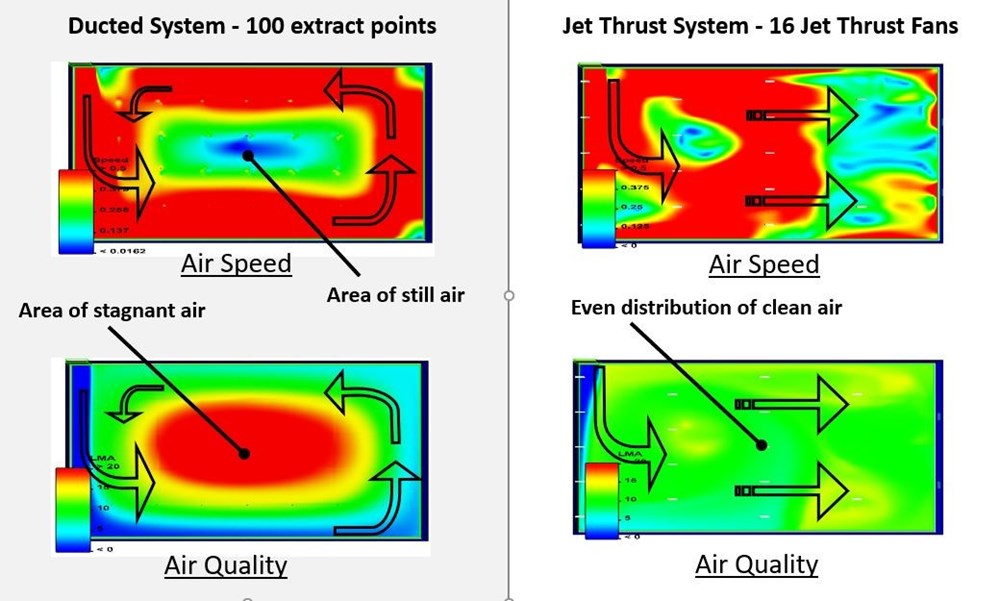

Figure 1: Comparison of Ducted and Jet Thrust Systems for pollution control

The advantage of a Jet Thrust System over a traditional Ducted System for such a Pollution Only set-up is that the supply air is spread more evenly across the parking garage making best use of the air, and avoiding areas of stagnant air in which pollution can rise to unacceptable levels (as shown in Figure 1).

Smoke Clearance or Fire Purging Systems

These are the most widely used method of mechanical ventilation in parking garages, a proven-over-time solution which is the simplest and easiest to demonstrate to approving authorities. The extract rate tends to be based on the parking garage dimensions, and is expressed in air changes per hour, or ac/h.

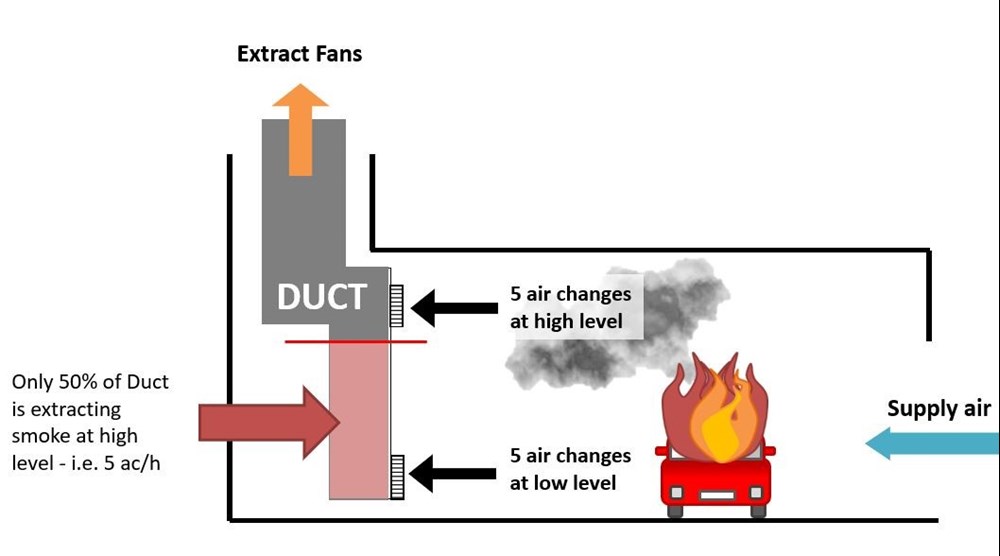

In a Ducted System containing both high and low level grilles, unless control dampers are fitted to each low-level dropper (an expensive option in terms of both installation and running costs), only half of the extract rate is applied to the smoke (upper) layer in the event of a fire, halving the effectiveness of the ventilation system (see Figure 2).

Figure 2: Reduced effectiveness of dual level Ducted System extract rate

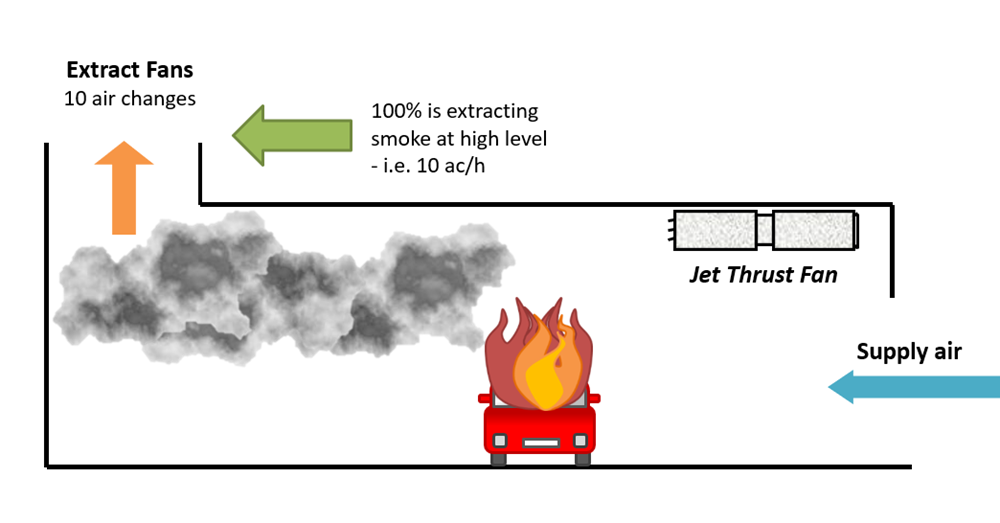

A Jet Thrust System removes the need for low-level grilles, because the air near the ground is entrained by the Jet Thrust Fans mounted at a higher level, extracting the smoke layer more effectively (see Figure 3).

Figure 3: Enhanced effectiveness of Jet Thrust System achieving 100% extract rate

Smoke Control Systems

This is the most enhanced design available for parking garage mechanical ventilation systems, and is best suited to large parking garages. This type of installation is designed around the requirements of controlling the smoke produced, and aiding firefighter access.

As such a system needs to incorporate an extract rate which is sufficient for an expected fire size, its design requires careful calculations to be made, in particular projecting the potential mass rate of smoke production and the likely smoke velocity.

The mass rate of smoke production is calculated taking into account factors such as the perimeter of the fire and the height of the clear layer beneath the fire.

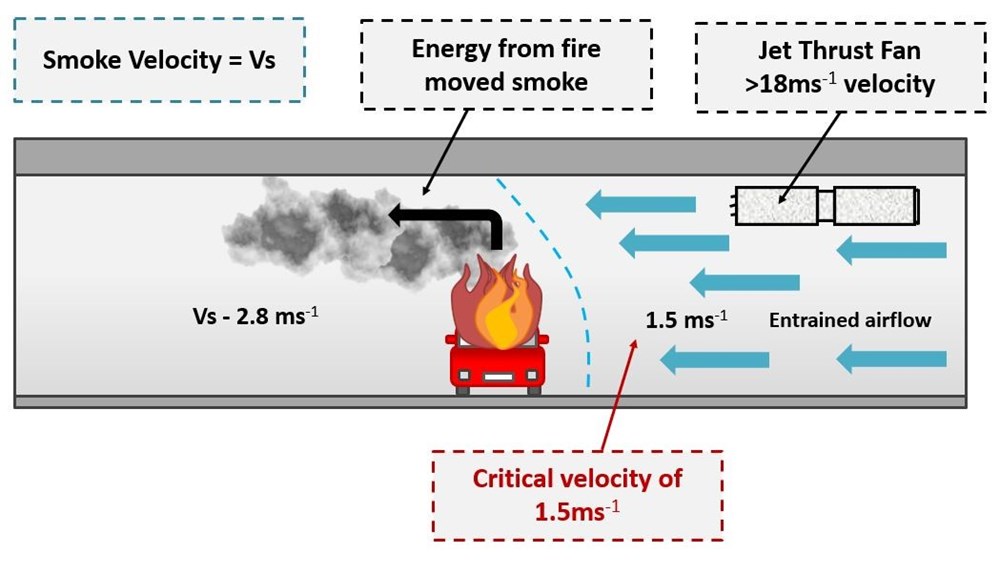

Once the mass of smoke has been worked, the smoke velocity (Vs) can be calculated using Heselden’s method of predicting smoke velocity.

Knowing the critical velocity of smoke spread at the point to which we want to control the smoke, Jet Thrust Fans can be used to halt the advancement of smoke in one direction, allowing occupants to escape towards, and firefighters to attend to the fire from, the other direction (see Figure 4).

Figure 4: Jet Thrust Fans halt the advancement of smoke in one direction

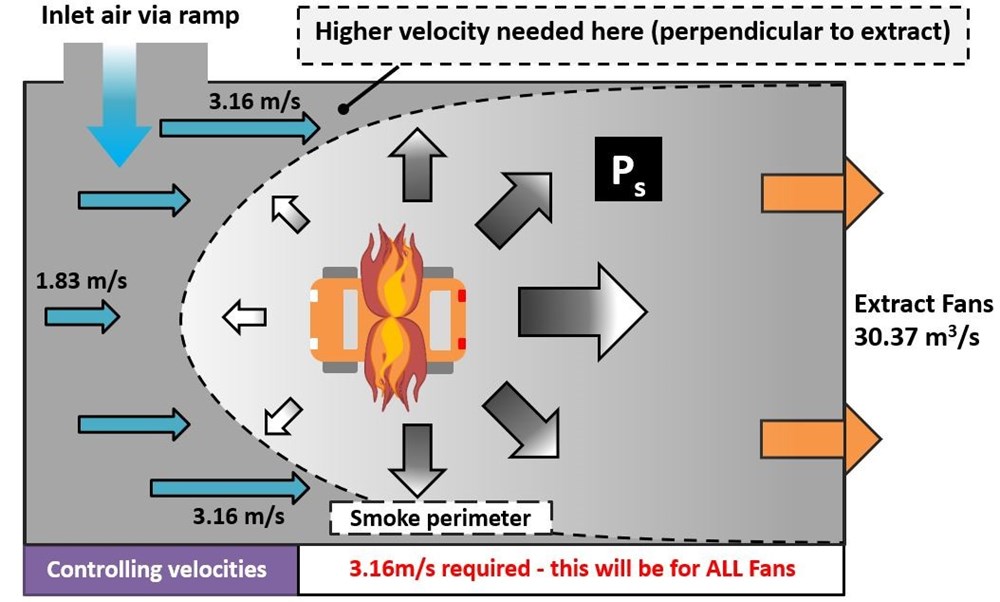

Unlike in a tunnel, where smoke can really only spread in two directions, in a parking garage the fire can spread in more directions. Here, standard tunnel theory needs to be adapted to calculate a smoke perimeter (Ps), which causes further consideration with regards to the controlling velocities. To change the direction of the smoke, a higher velocity is required than that needed merely to halt its spread.

This means that this higher velocity will be required across the whole parking garage area to ensure smoke control. This higher velocity will be required for all fans over the cross-sectional area of the parking garage (see Figure 5).

Figure 5: A higher velocity is required across the whole parking garage to ensure smoke control

By using a reversible Jet Thrust System, the air can be directed to the closest extract location, negating the need to extract smoke across a wide area of parking garage, and minimizing the portion of the parking garage affected.

Balancing The System

A critical point with Smoke Control Systems is that the amount of air moved with the Jet Thrust Fans and the amount of air extracted has to be balanced. If the Jet Fans move more air than the extract is able to remove, there can be an increase in the recirculation of smoke, leading to reduced visibility and increased smoke spread across the parking garage.

Jet and extract balance can be achieved by turning down, or off, Jet Thrust Fans, although sufficient Jet Fans need to be operational to control the smoke at its source, and this number increases as the parking garage and/or the fire itself become larger (and also when sprinkler protection is removed or for elevated fire loads such as those in loading bays and bus parks).

In these cases, the Extract Fan duty must be increased to match the flow rate of the Jet Fans.

CLICK HERE TO READ PART 42020-10-27